As often as we use and see brass shells on the ground, there are many people who are unfamiliar with the process of forming brass casings. The process of manufacturing brass casings is long, labor intensive and strangely, delicate.

The life of each brass casing evolves from a brass coil that is made from a combination of zinc and copper. Copper makes up about 70 percent of the alloy, and zinc is the remaining 30 percent. This is pretty standard throughout the ammunition industry. The process starts with a brass disk stamped from strips of metal.

THE STEPS FOR MAKING BRASS SHELL CASINGS:

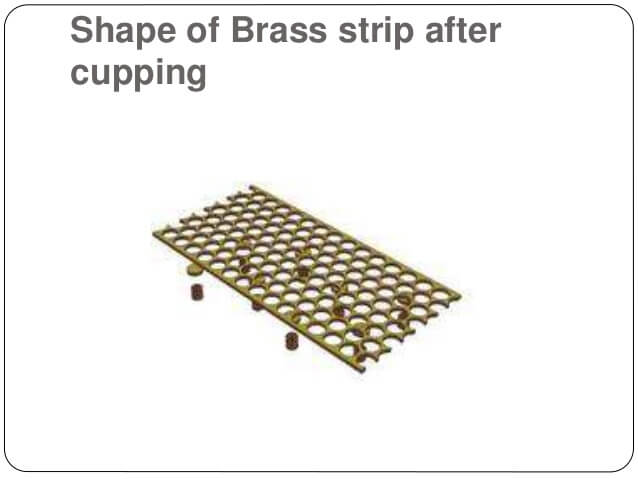

The Cupping Process is the first step and it essentially involves feeding a coil of brass into an automated cupping press, which generates small “cups” of brass. The residual scrap brass that results is remelted to form more coils. The small cups are initially wide and deep.

The Draw Process: The cups undergo a series of steps that cause the brass to appear into a cylindrical shape. This may be done with an extrusion process or a draw process. During the initial extrusion phase, the brass is squeezed through a die under extremely high pressure. In the traditional draw process, the brass casing is progressively stretched over 3-stages using high-pressure reams, which forces the brass to form into a tube.

During the process, the cup is heated and elongated to form what looks like a primitive shell. Following each draw/extrusion, the brass is annealed, pickled, and rinsed. At each step, the brass dimensions are measured. This initial process causes the shell to harden and becomes resistance to the stress of heat and pressure.

The Pinch Trim follows the draw process and here the extra metal at the top of the cup is pinched off –this results in a trimmed miniature tube.Once the miniature tube is set, the next step is the formation of the Primer Pocket and application of the head stamp at the bottom of the casing.

The casing is essentially jammed and a hard steel plug called a bunter is used to create a primer pocket. This is followed by a head stamp, which results in raised letters or numbers.

The Extractor Groove is cut using a horizontal lathe. The casing is clamped on a spindle and rotated at high speed while the profile cutter is pressed against it. The fast rotation motion creates the casing’s extraction groove.

Next, Three Tapers are done which lead to the development of the neck, body, and mouth. By the end of the three tapers, the casing has its final neck, body, and mouth dimensions. But in most instances, the casing is still slightly too long and does not have a flash hole yet.

The elongated shell is then Trimmed to length and mouth chamber adjusted using the cutter.

The next step is to cut a Flash Hole, which does require some precision. The flash hole is made either by drilling or a punch through the brass. This process may leave rough edges around the new opening. The flash hole in casings should be free of any tearing or burrs and must also be of uniform size.

Finally, the casing undergoes Annealing at the mouth and neck. This important step ensures that the when the casing is fired, it will have a uniform and correct projectile path. One can anneal using induction or flames. Most manufacturers prefer induction annealing as it enables better control of temperature so that there is uniformity in all casings.

FINAL STEPS IN BRASS CARTRIDGE MANUFACTURING

It is vital that between each step (listed above), the shell casing is thoroughly washed. Most Brass manufacturers use more than just a detergent and water for washing. There are now commercial washes that contain detergent, acids and anti-rust proof chemicals that are used to wash the brass shells during each step of manufacturing. The wash removes any excess lubricant, debris, and tarnish that may have developed during the process. The end result is a polished shiny-looking brass casing.

The final product is approved by quality control processes and sent for packaging in bulk drums, pallets or even railcars for delivery to ammunition manufacturers.

Next time you pick up a brass shell, think about the multi-step process that went into the first making of a casing to be used in manufacturing ammunition and then in reloading. For range brass and once fired brass, let Capital Cartridge fill your orders with our in stock supply of bulk brass or sell us your range brass.

www.GunsandOptics.com Tactical & Hunting Gear Review

www.GunsandOptics.com Tactical & Hunting Gear Review